The supply chain that finds innovative ways to manage the right risks in the right way will beat out the competition when the next crisis inevitably strikes.

This article will take about 4 minutes to read

As organizations anticipate the end of the pandemic, it is becoming obvious that business as usual will be anything but. Few industries will be able to return to the environment that existed before COVID-19. Even as coronavirus cases decline and daily work resumes, things are going to look very different. With this in mind, supply chain leaders are already thinking long-term about what this new world will look like within their organizations.

How the Pandemic Changed the Supply Chain

Many supply chain leaders have transitioned from the uncertainty by adopting new ways of working to stabilize their business. Now it’s time to begin thinking strategically about how to position operational networks for life beyond the pandemic. Designing a supply chain that is both resilient and agile, can withstand risks to both demand and supply, and can quickly respond to shocks.

The first step is to conduct a rigorous review of the impact COVID-19 is having on both the demand and the corresponding performance of the supply chain. This will require drilling down to the specifics of how the pandemic has already affected demand. This will build the basis of how demand might change in the future.

To build a framework for a post-pandemic review, considering these impacts of the coronavirus outbreak is a good start:

- Demand has shifted. The demand for many products saw a rapid increase; others saw a rapid decline. Some are no longer a priority and may be gone for good.

- Customer behaviors have changed. Internet purchasing is skyrocketing in some industries. Brick-and-mortar retail may never be the same.

- There are new customers. People have reprioritized their wants versus their needs. This has affected what they buy and who they buy it from.

- Portfolios are back to the drawing board. Certain SKUs are no longer important. In other cases, product needs in a post-COVID world are being rapidly redesigned.

Similarly, the impacts on supply will also require a post-pandemic review:

- Supply chains were disrupted during the pandemic. The COVID-19 outbreak caused major shifts. From transitioning supply planners so they can work from home, to finding alternative sources for suppliers that are under lockdown, to keeping employees safe and manufacturing capacity available.

- Some supply areas performed well while others struggled. New best practices were learned and will be capitalized on. As a result, risky practices will be eliminated.

- Structural elements exacerbated supply issues. Global supply chains will be questioned as geography experienced the pandemic in phases. Suppliers, manufacturers, and distributors were cut off from one another.

- Technology is essential. Responding during a crisis requires real-time data about where materials and products are, as well as the status, location, and health of employees in plants and warehouses. It also requires control towers that can orchestrate operations from end to end.

These impacts will influence how the supply chain and operations will need to be upgraded for resiliency and preparedness, as well as what the long-term structure should look like. Historically, operations strategy focused on balancing cost reduction as well as investments to improve availability performance and lead times. Business risk was important, but it was typically addressed with relatively simple approaches. These included maintaining safety stock at distribution centers or establishing one-off secondary supplier relationships. Responding to a global crisis was rarely part of the picture.

Changing Management Focus

Clearly, there are changes to be made. If the pandemic has taught us anything, it’s that the leaders need to make risk management an equal consideration to supply chain strategy.

It is now far more important to understand how resilient, as well as how exposed, the supply chain is. The leaders are viewing the major components of their operations with a fresh eye for resiliency and agility. This includes labor, technology, and capacity. For instance, the ability to flex or repurpose assets rapidly or balance automation and labor are now more important than ever.

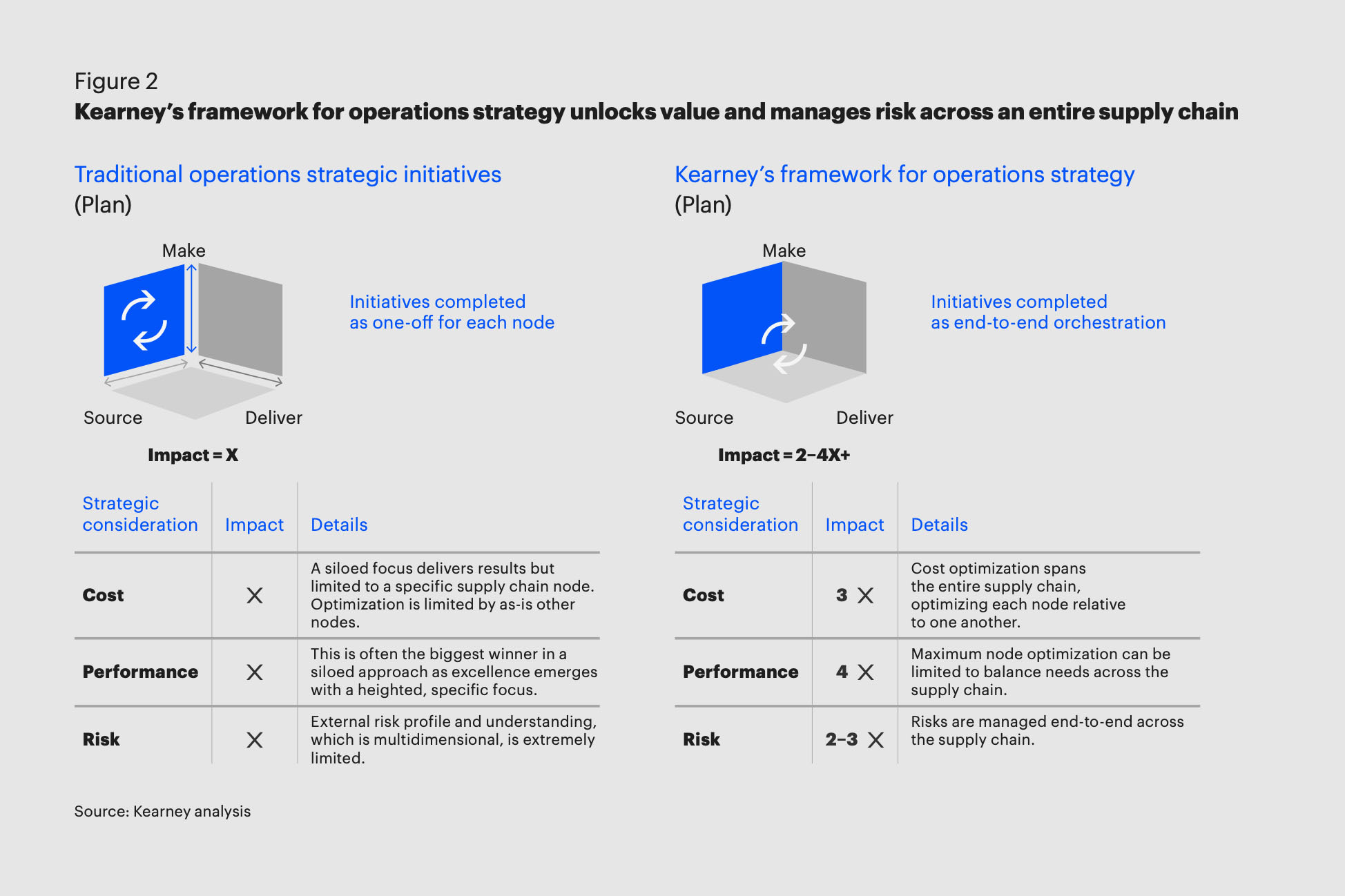

Traditionally, operations improvements have been little more than the combination of functional or siloed optimizations. Improvements in planning, manufacturing or procurement were frequently completed as one-offs within each function. Although a siloed approach does deliver results, success is limited to the specific function. Operating in a post-COVID world will require a comprehensive framework as well as an approach that not only unlocks value but does so by managing risks across the entire chain.

Leaders have always wanted to deliver the lowest cost at the best performance. However, now the price of resiliency will be layered into supply chain design—and the value equation will change.

Kearney’s Approach to Supply Chain Operations

This cross-functional view of risk is core to Kearney’s framework for operations strategy. With our approach, optimization spans the entire supply chain, and each function is optimized simultaneously— balancing needs across each area to maximize end-to-end supply chain performance and minimize cost. Our framework not only factors in internal and external risks but also enables proper tradeoff assessments in real-time.

Furthermore, with our approach, the strategic mindset changes from:

- One piece of the supply chain limiting the other, to all pieces working collectively

- Individual functions blaming one another for roadblocks, to all functions collaborating to remove obstacles

- Overengineering single areas while neglecting others, to making changes based on an organization-wide assessment

- A limited and inaccurate understanding of supply chain risk, to a comprehensive, end-to-end view

To us, supply chain risk is an equal input to cost and performance. But one size does not fit all. Every company will have had a different experience during the COVID-19 crisis. Therefore, the views on risk will be unique to that experience.

For example, a company with zonal manufacturing will have a much different view than a company that purchases everything overseas. Similarly, a company that doesn’t have the skills to produce products in other regions will not necessarily move operations to a new region as a result of the pandemic.

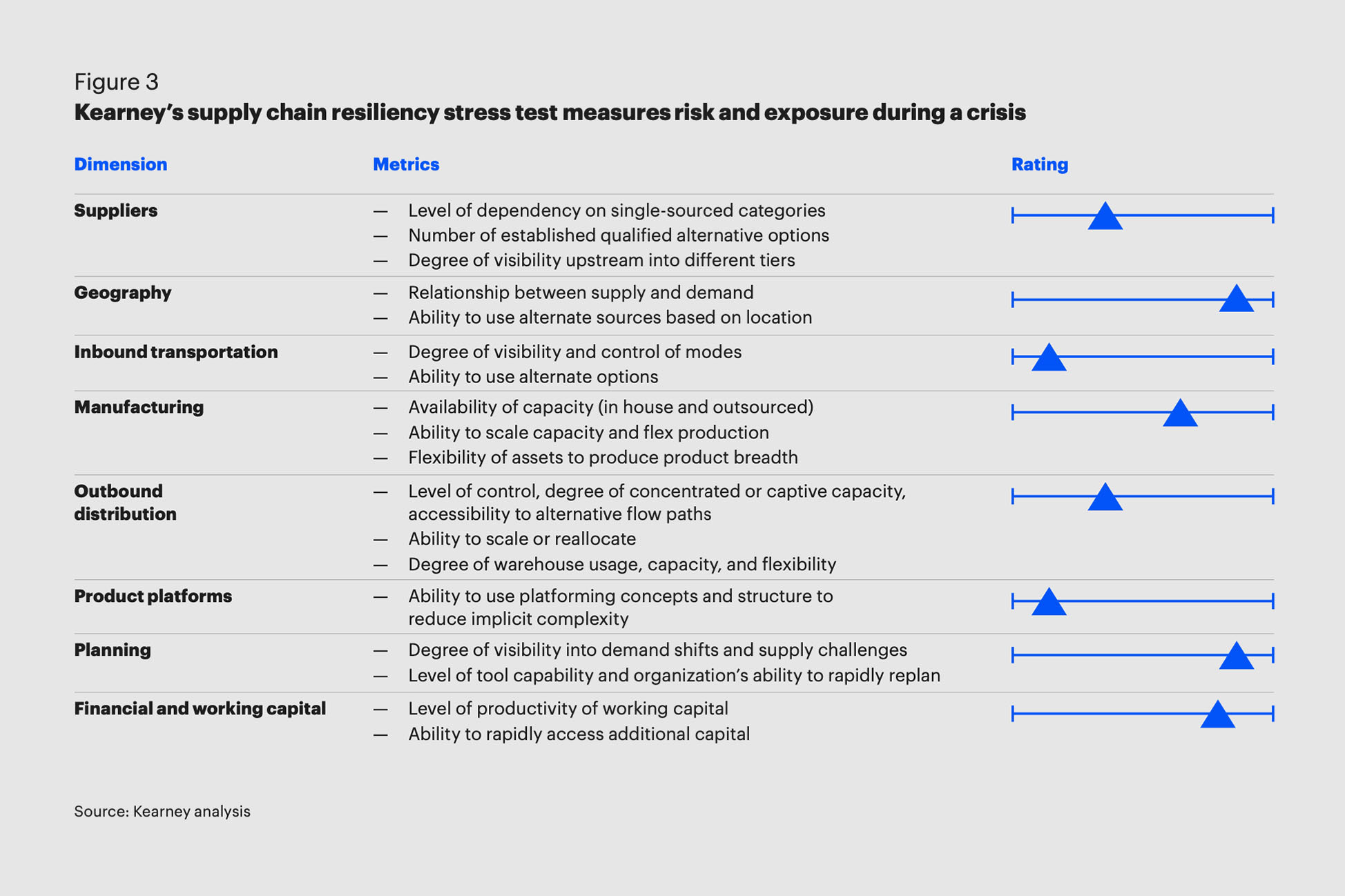

Whatever the unique circumstances are for an enterprise, we begin with an understanding of what happened with consumer demand for products, customer behaviors, as well as channel dynamics. Then, we pivot to determine how resilient the supply chain was during the pandemic. Using Kearney’s resilience stress test, we quantify the dimension and magnitude of exposure.

Then, we calibrate it with the actual performance during the COVID-19 crisis and use it to predict where challenges and failures may occur in the future.

Using the insights from these resiliency measures, we can predict where the points of stress are likely to occur and, more importantly, where we can deploy strategies to mitigate these risks. It is important to note that being risk savvy also means understanding wherein the supply chain we could sacrifice cost or performance to reduce the exposure to risk.

Evolving the Supply Chain

As the world advances toward recovery, supply chain strategy will need to evolve to incorporate the lessons learned during this pandemic. That means moving away from a narrow focus on cost and availability to a more comprehensive perspective that incorporates risk as well as resilience factors. In fact, supply chain organizations that are designed to manage the right risks in the right way will ultimately beat out the competition when the next crisis inevitably strikes.

About Kearney

As a global consulting partnership in more than 40 countries, our people make us who we are. We’re individuals who take as much joy from those we work with as the work itself. Driven to be the difference between a big idea and making it happen, we help our clients breakthrough.

Steve Mehltretter

President of A.T. Kearney Canada

Venky Arun

Vice President at A.T. Kearney

Will Shalosky

Principal | Operations Strategy at A.T. Kearney

Kip Dowding

Principal at A.T. Kearney